Milk is an important source of nutrients not only for children, but for adults as well. With its great importance, milk is available in several different forms: fresh, boxed (ultraheat treated), powdered, and evaporated. The most commonly consumed form varies globally, being dependent on factors such as geography, culture, and climate.

Analysis of nutrients in milk is an important facet in monitoring milk quality. Micronutrients can either be present naturally or added to fortify the milk, reflecting market demands and, in some cases, regulatory requirements. Regulatory oversight and the mandatory addition of nutrients continues to grow as organizations seek to prevent systemic malnutrition and guarantee that the milk is unadulterated. Populations are also responding by requesting the monitoring of micronutrients to improve the quality of milk and by selecting fortified products over non-fortified products in the marketplace.

For milk producers, internal quality control and the possibility of external monitoring provide strong incentives for the ability to quickly, accurately, and easily monitor nutrients in their products. In addition, nutritional labeling guidelines also require an accurate assessment of nutrients for regulatory compliance.

Quang phổ phát xạ nguyên tử plasma cảm ứng (ICP-OES) Inductively coupled plasma optical emission spectroscopy (ICP-OES) is generally favored in a multi-element analytical environment with detection capabilities appropriate for nutritional analysis and offering a large dynamic range, rapid multi-element throughput, and robust operating conditions. Flame atomic absorption (AA) systems, which provide cost savings, simplicity, and single-element analytical speed, can be attractive alternatives1. However, measuring multiple elements by flame AA requires each sample to be analyzed individually for each element, which eliminates the speed advantage of flame AA for multi-element analysis.

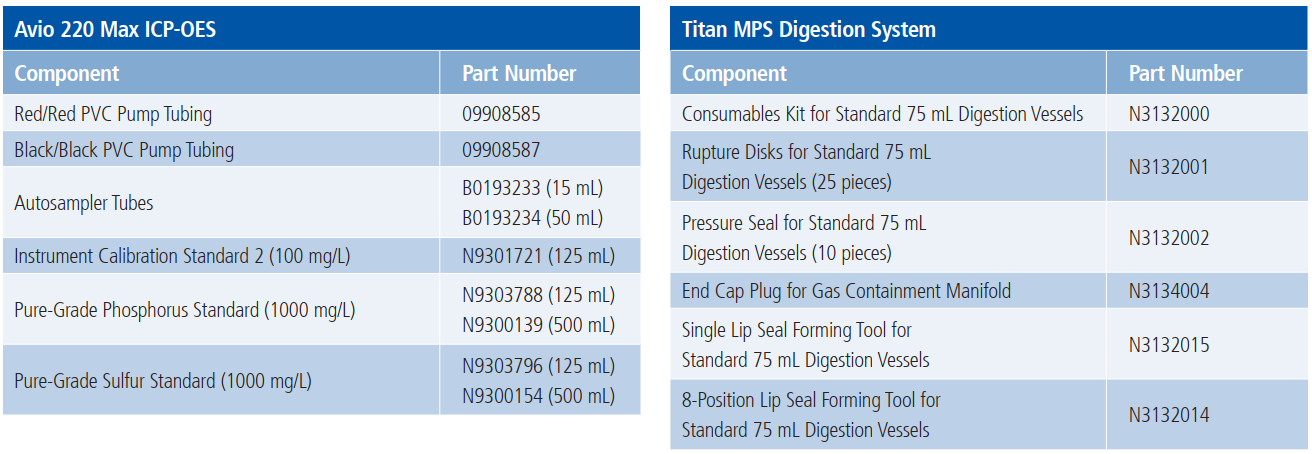

This work focuses on the analysis of micronutrients in a variety of commercial milk products using a PerkinElmer Avio® 220 Max hybrid simultaneous ICP-OES with sample preparation using a PerkinElmer Titan MPS™ microwave digestion system. hệ thống ICP-OES lai Avio® 220 Max với quá trình chuẩn bị mẫu sử dụng hệ thống phân hủy vi sóng Titan MPS™ của PerkinElmer.

Experimental

Samples and Sample Preparation

Samples were purchased from local markets and were selected to be representative of commonly available milk varieties, in both fresh and non-perishable forms. The samples analyzed represent whole, reduced-fat, and non-fat versions of fresh, evaporated, boxed, and powdered milk, along with NIST SRM 1549a Whole Milk Powder. The analytical elements selected are nutrients commonly found in dairy and dairy-based products.

The milk samples were prepared for analysis by closed-vessel microwave-assisted digestion using a PerkinElmer Titan MPS microwave digestion system. The digestion method, sample parameters, and reagents used are listed in Tables 1 and 2. Samples were weighed and placed into the digestion vessels, and then the reagents and any sample spikes were added. The samples and reagents then sat open in the vessels for 10 minutes to allow any early reactions to occur safely before being sealed and placed into the Titan MPS for digestion. After digestion was complete, the samples were transferred out of the digestion vessels by triplerinsing with deionized (DI) water into sample vials for analysis.

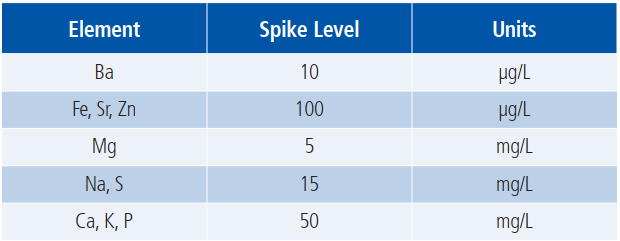

Table 1: Titan MPS Digestion Method

Table 2: Digestion Infomaton

Instrumental Conditions

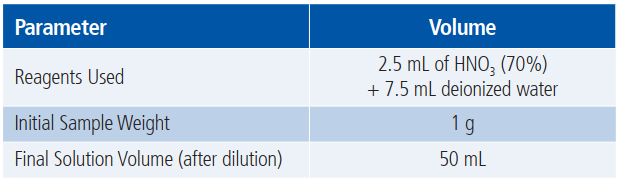

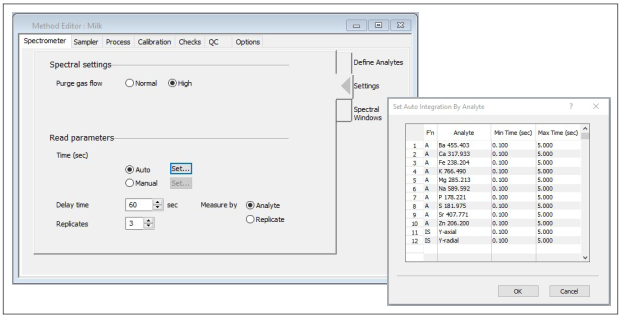

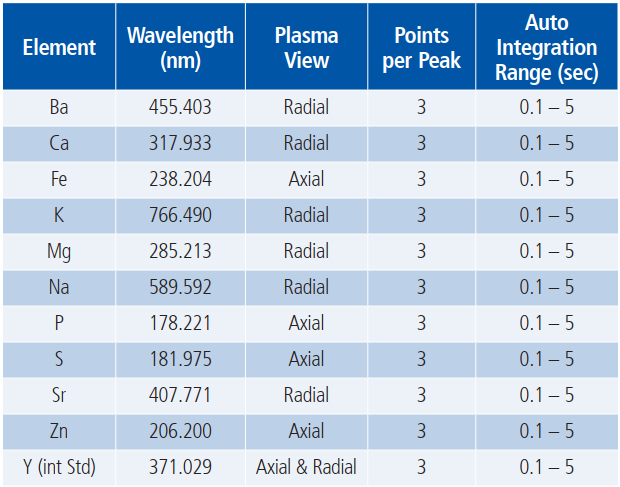

Tất cả các phân tích được thực hiện trên hệ thống ICP-OES lai Avio 220 MaxAll analyses were performed on an Avio 220 Max hybrid simultaneous ICP-OES. The elements of interest and instrument conditions for the analysis of the milk samples are outlined in Tables 3 and 4. The standard sample introduction system was used, consisting of a MEINHARD® glass nebulizer and baffled glass cyclonic spray chamber. For analysis, an auto integration range of 0.1-5 seconds was used for each element. This wide range allowed the Avio 220 Max spectrometer to automatically determine the most appropriate integration time for each element: higher-concentration analytes were read with a shorter time, while lower-concentration elements used a longer integration time (Figure 1). This capability minimizes sample analysis time and, combined with the low argon consumption (8 L/min), results in a significant savings when considering the cost of argon.

Figure 1: The auto integration capability in Syngistix for ICP software automatically determines the most appropriate integration time for each element, minimizing sample analysis time

Table 3: Avio 220 Max Hybrid Simultaneous ICP-OES Instrumental Parameters

Table 4: Method Parameters

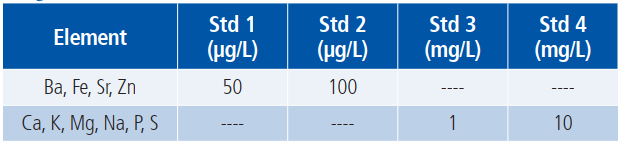

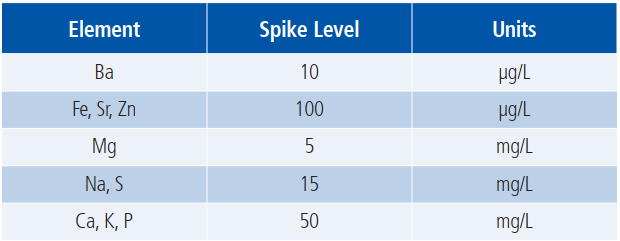

External calibration standards were prepared in 5% nitric acid (v/v) from a multi-element stock and two single-element standards at the concentrations listed in Table 5. The calibration standards were prepared in two ranges to allow maximum accuracy for both low- and high-level elements. The final nitric acid concentration of the standards (5%) was chosen to match the acid concentration of the digested and diluted samples. Yttrium (Y) was added to all solutions at 0.5 ppm as an internal standard.

Table 5: Calibration Standards

Results and Discussion

Despite the differences in the milk samples (fat content, density, form), the Titan MPS digestion system was able to simply and quickly prepare them for analysis using a minimal quantity of reagents, providing major time savings over typical open-vessel digestions. All digests yielded clear solutions, which indicates a complete digestion.

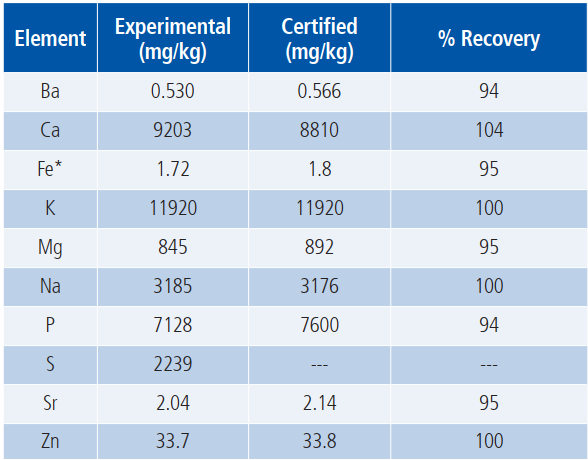

To establish the accuracy of the method, NIST 1549a Whole Milk Powder was analyzed, with the results appearing in Table 6. This was the most challenging sample due to its high fat content and concentrated (powder) form. Nevertheless, all recoveries are within 10% of the certified values, demonstrating the accuracy of the methodology and highlighting the ability of the Avio 220 Max ICP-OES to measure large variations of elemental concentrations in a single analysis.

Table 6: Analysis of NIST 1549a Whole Milk Powder

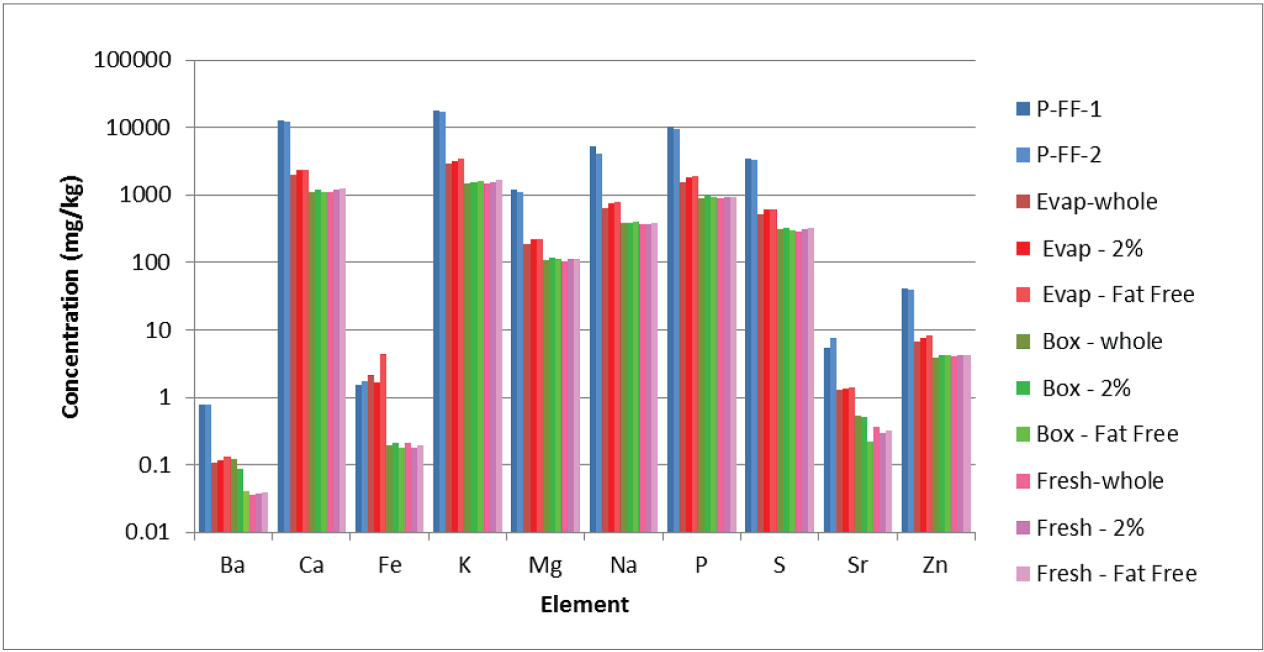

With the accuracy established, the other milk samples were analyzed, with the results appearing in Figure 2. As expected, the concentration of elements in the powdered milks was the highest, followed by the evaporated milks as well as boxed and fresh milks, which had the lowest elemental concentrations.

It is interesting to note that the elemental concentrations are consistent within a sample type (i.e. boxed, fresh, evaporated, or powdered), regardless of the fat content. In addition, the boxed milks contain the same nutrient levels as the fresh milks, indicating that the ultra-heat treatment of the boxed milks (required to keep them stable without refrigeration) does not degrade the nutritional quality. This analysis also shows why milk is such a valued food source: nutrients (such as calcium, potassium, magnesium, and sodium) are present at elevated levels, along with phosphorus and sulfur.

Figure 2: Results from analyses of milk samples (powdered milks in shades of blue, evaporated milks in shades of red; boxed milks in shades of green; fresh milks in shades of pink)

With the large dynamic range available and the dual view capability of the Avio 220 Max ICP-OES, it was not necessary to make custom dilutions per element. With two levels of calibration standards (as shown in Table 5), all elements could be analyzed in a single analytical pass per sample.

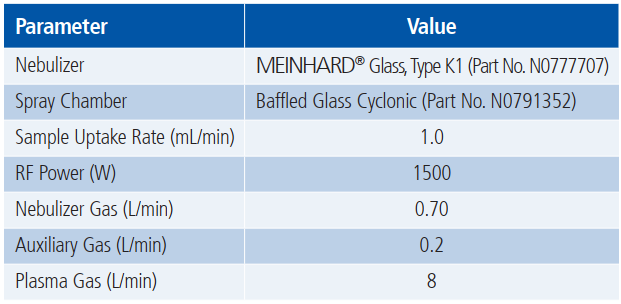

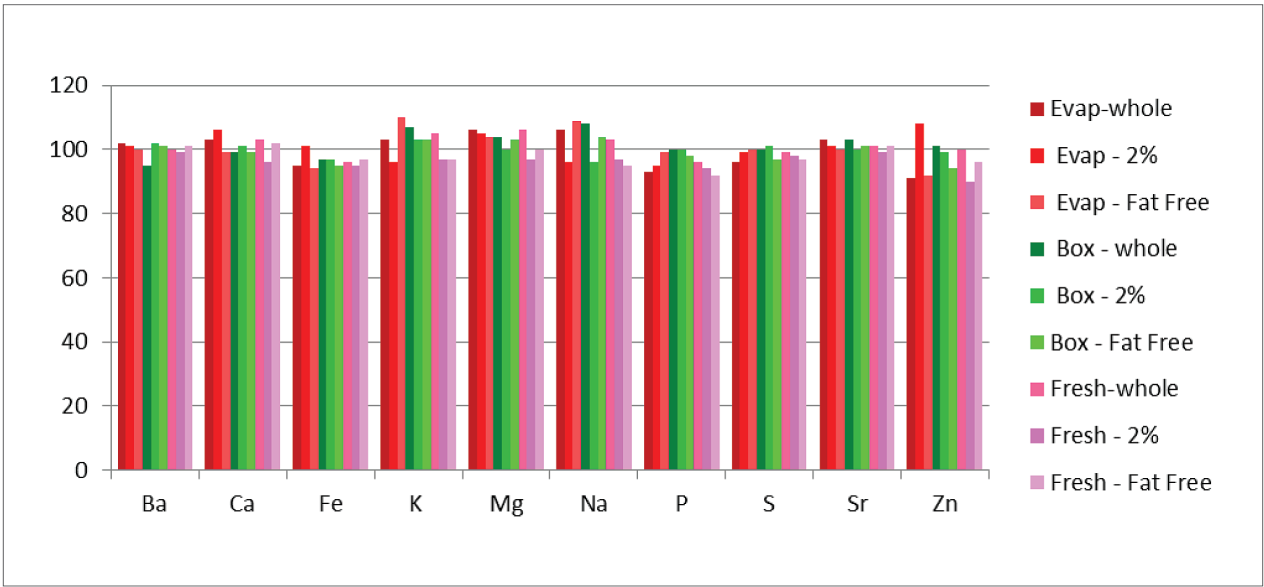

To assess any remaining matrix effects from the various samples, all of the evaporated, boxed, and fresh milks were spiked prior to digestion with all elements at the levels shown in Table 7. These spike levels represent the concentrations in solution after sample preparation and are slightly higher than the concentrations of the unspiked milks. This criterion ensures that the spike level is meaningful in relation to the sample signal for the purposes of analytical evaluation. The powdered milk samples were not spiked since analysis of the NIST milk powder demonstrated the absence of matrix effects. The resulting spike recoveries appear in Figure 3: all fall within 10% of the spiked value. With the effective digestion provided by the Titan MPS system, per-sample matrixmatching was not required to achieve excellent spike recovery.

Conclusion

This work has demonstrated the ability of the Avio 220 Max hybrid simultaneous ICP-OES to reliably and effectively analyze a variety of milk samples for an array of elements over a wide range of concentrations. With its extended capabilities, the Avio 220 Max spectrometer provides greater multi-element sample throughput when compared to flame AA, while allowing simple analysis of elements, which are typically challenging for flame AA, such as phosphorus and sulfur.

Table 7: Pre-Digestion Spike Levels

Using the Titan MPS microwave digestion system simplified sample preparation while increasing throughput and productivity for the laboratory compared to hot plate or hot block digestions. The ability to completely digest the samples eliminates the need to matrix-match calibration standards, thus simplifying the analysis.

The use of the Titan MPS digestion system for sample preparation and the Avio 220 Max ICP-OES for analysis is an ideal combination for fast, simple, and accurate analyses of nutritional elements in milk.

Figure 3: Spike recoveries in milk samples (evaporated milks in shades of red; boxed milks in shades of green; fresh milks in shades of pink)

References

- Spivey, Nick, “Analysis of Micronutrients in Milk by Flame Atomic Absorption Using FAST Flame Sample Automation for Increased Sample Throughput”, Application Note, PerkinElmer, 2015.

Consumables Used

Detail app note: https://perkinelmer/content/app-avio-icp-oes-milk-micronutrients.pdf?u=3ezgsz