With the wide application of lithium-ion batteries, researchers are currently focusing on further improving their performance and safety. As one of the key raw materials, the quality of lithium carbonate (Li2 CO3 ) plays an important role in the electrochemical properties of the battery, where even small amounts of contaminants in Li2 CO3 can affect the characteristics of the battery. For example, excess sodium (Na) can lead to overheating, reducing the battery life and causing explosive events. Table 1 lists the maximum allowable impurity concentrations in battery-grade Li2 CO3 (≥ 99.9%) according to China industry standard YS/T 546-2021 for high-purity lithium carbonate1.

Phổ phát xạ plasma cảm ứng cao tần (ICP-OES) Inductively coupled plasma optical emission spectroscopy (ICP-OES) is a widely used technique to meet the requirements of YS/T 546-2021 due to its advantages of multi-element analysis capabilities, low detection limits, and high matrix tolerance. However, the main challenge when measuring samples with high levels of lithium salts is the easily ionizable element (EIE) effect: since Li has a low ionization potential (5.39 eV), its presence at high concentrations affects the responses of other elements which have low ionization potentials (i.e. potassium = 4.34 eV and sodium = 5.14 eV), causing inaccurate results2. Although axial view offers higher sensitivity and is normally recommended for impurity analysis, the EIE matrix effect is more severe than radial view, making accurate analysis difficult. In addition, robustness of the instrument is needed for the analysis of a large number of lithium matrix samples.

Table 1. Specifications for > 99.9% Li2 CO3 in Standard YS/T 546-2021

This work presents a method for accurate and robust impurity analysis in Li2 CO3 samples to meet the requirements of YS/T 546-2021 using the Avio® 550 Max fully simultaneous ICP-OES.

Experimental

Sample Preparation

One unknown battery-grade Li2 CO3 sample and one 99.998% purity Li2 CO3 sample (Sigma-Aldrich) were analyzed. A 0.5 g quantity of each sample was weighed into a polypropylene digestion tube, followed by slowly adding 5 mL of 1:1 (v/v) HNO3 and heating the sample solution in a Sample Preparation Block system (SPB, PerkinElmer) at 120 °C for 30 minutes. The solutions were then cooled to room temperature and diluted to 50 mL with deionized water.

Calibration Standard Preparation

To minimize matrix effects, a matrix stock solution was prepared separately by dissolving 2 g of 99.998% Li2 CO3 in 100 mL of 10% HNO3 . The calibration standard solutions were prepared by adding PerkinElmer single- and multi-element standards to the matrix solution. The concentration of analytes in calibration standards are listed in Table 2.

Table 2. Concentration Range of Analytes in Calibration Standards.

Instrumentation

Tất cả các phân tích được thực hiện bằng the Avio 550 Max fully simultaneous ICP-OES, All analyses were performed using an Avio 550 Max fully simultaneous ICP-OES, which features a unique echelle optic and segmented-array charge coupled device detector (SCD)3, providing high-speed analysis and simultaneous measurements of all elements. The proprietary Flat Plate™ plasma technology4 delivers a robust plasma which, along with the vertical torch, ensures the measurement stability of high-matrix samples. Universal Data Acquisition (UDA)5 allows collection of all the spectral data for every sample in a single run, which provides flexibility of wavelength selection for all elements and simplifies method development, an important consideration for impurity analysis.

Further simplifying method development for impurity analysis is SmartQuant™, a module in Syngistix™ for ICP software which provides rapid analysis of all elements capable of being measured on the Avio 550 Max ICP-OES6. SmartQuant quickly answers the questions “What elements are in this sample? And how much?” Built on UDA, SmartQuant rapidly measures all elements, displays their spectra, and provides semi-quantitative results displayed as a heatmap on the periodic table. These results guide method development by showing which elements are present and at what levels, so that quantitative analysis can be performed on the impurities present.

Although the Avio 550 Max fully simultaneous ICP-OES, has standard dual view capabilities, permitting analysis of any wavelength in radial and/or axial views, its excellent sensitivity allows all the analytes to be analyzed in radial view to minimize the EIE matrix effect. A PEEK MiraMist nebulizer and baffled cyclonic spray chamber were used, which enable the analysis of samples containing high total dissolved solids (TDS) with less dilution. The instrument operating parameters and the wavelengths of the analytes are listed in Tables 3 and 4.

All analyses were performed using auto integration with a readtime range of 0.5-10 seconds. With auto integration, the Avio 550 Max ICP-OES automatically decides the most appropriate integration time per analyte based on a pre-shot. This optimizes sample throughput as short integration times are applied to analytes present at high concentrations, while longer integration times will only be applied to analytes with low concentrations, thereby providing fast analysis for high-level analytes while also allowing for accurate measurements of low-level analytes.

Table 3. Instrumental Parameters.

Table 4. Elements and Wavelengths.

Results and Discussion

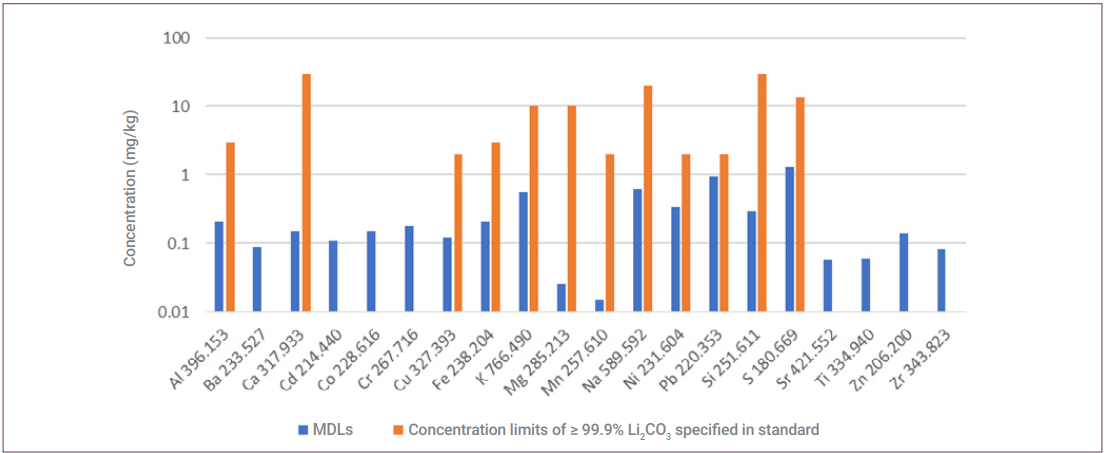

The standard addition method was used to compensate for the high levels of lithium salts and improve accuracy for the determination of impurities in the lithium matrix samples. Excellent linearity for all analytes was obtained, with calibration coefficients greater than 0.999. The method detection limits (MDLs) were determined by measuring 10 replicates of the 1% Li2 CO3 blank solution and calculated by multiplying the SD of the 10 replicates by 3; these values were multiplied by 100 to account for the dilution factor. As shown in Figure 1, the measured MDLs of all analytes (except sulfur) in the solid are below 1 mg/kg, demonstrating the excellent sensitivity in radial mode of the Avio 550 Max ICP-OES. With these detection limits, the method is well suited for the determination of these analytes in high-purity-grade Li2 CO3 matrix samples with purity ≥ 99.9%, as specified in the quality standard.

Sample and Spike Recovery Results

The results for the two Li2 CO3 samples are listed in Table 5 and show that the unknown Li2 CO3 sample has a purity greater than 99.9%, meeting the requirements for battery-grade Li2 CO3 , as defined by standard YS/T 582-20137. Comparing the results with 99.998% purity Li2 CO3 , sulfur and sodium show the largest differences, since sodium- and sulfur-containing compounds (Na2 CO3 , H2 SO4 ) are used during production, whether from ores, brines, or clays8.

Table 5. Sample Results.

Figure 1. MDLs in solid Li2 CO3 measured and limiting concentration of ≥ 99.9% Li2 CO3 specified in YS/T 546-2021.

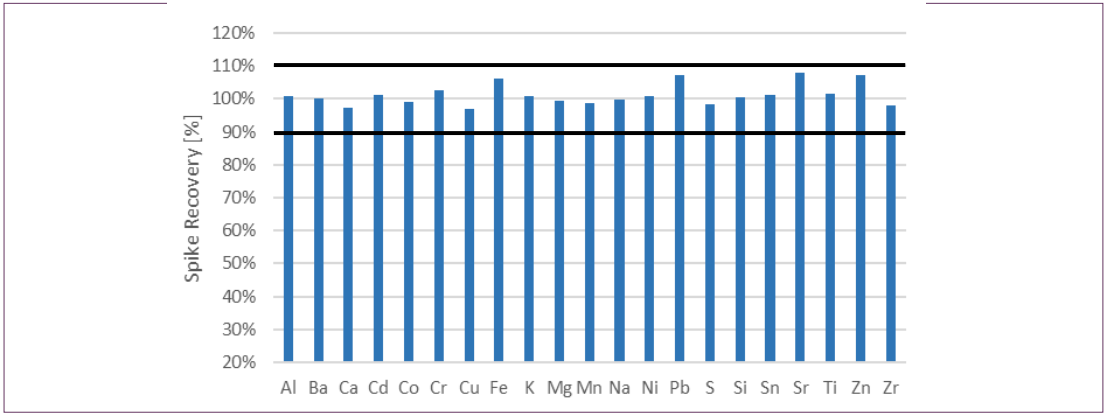

A spike recovery analysis was performed to investigate the accuracy of the results. Considering the measured concentration of the elements in the unknown Li2 CO3 sample, 0.5 mg/L for sodium and sulfur and 0.02 mg/L for other analytes were spiked into the prepared solutions, which is equivalent to 0.005% of Na and S and 0.0002% of the analytes in the solid sample. As shown in Figure 2, the recoveries for all the analytes measured are within ± 10% of the expected values.

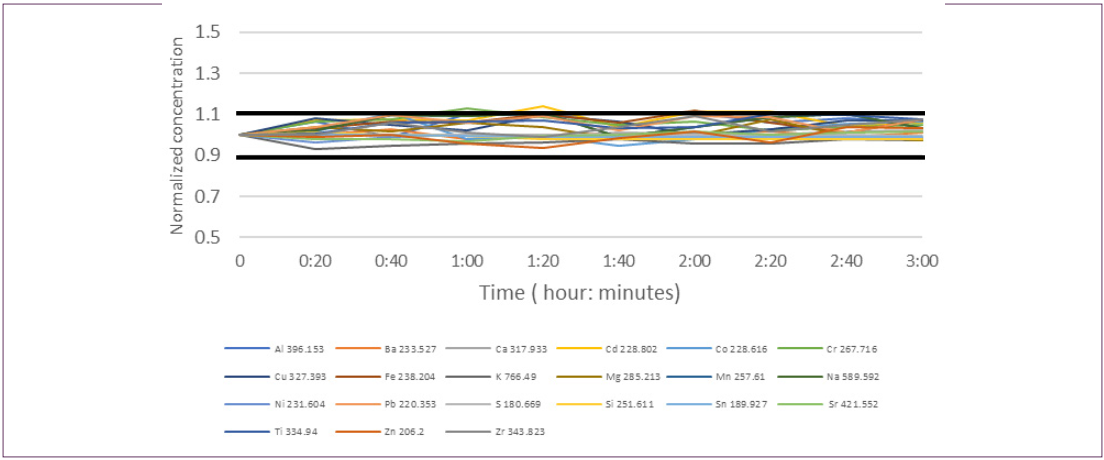

To check the instrument stability, a spiked sample was analyzed at regular intervals for 3 hours. As shown in Figure 3, the recoveries for all elements were within ± 10% of the first reading, indicating that this method has good stability and reliability.

Conclusion

In this work, a total of 20 elements in Li2 CO3 were determined the Avio 550 Max fully simultaneous ICP-OES, providing excellent detection limits, accuracy, and stability. The results demonstrate that the Avio 550 Max can fully meet the detection limit requirements specified in standard YS/T 546-2021 for battery-grade Li2 CO3 of ≥ 99.9%. To accurately characterize higher grades of Li2 CO3 , it is recommended to use inductively coupled plasma mass spectrometry (ICP-MS)9,10.

Figure 2. Spike recovery results in 1% Li2 CO3 (0.5 mg/L for Na and S and 0.02 mg/L for other analytes).

Figure 3. Long-term stability for 3 hours

References

1. Chinese Standard YS/T 546-2021, High Purity Lithium 1. Chinese Standard YS/T 546-2021, High Purity Lithium Carbonate, https://www.chinesestandard.net/AMP/Related.amp.aspx/YST546-2021.

2. “Concepts, Instrumentation and Techniques in Inductively Coupled Plasma Optical Emission Spectrometry”, PerkinElmer Corporation, 1997.

3. “Avio 550/560 Max ICP-OES Optical System and SCD Detector”, Technical Note, PerkinElmer, 2020.

4. “Flat Plate Plasma Technology on the Avio Max Series ICP-OES”, Technical Note, PerkinElmer, 2020.

5. “Universal Data Acquisition in Syngistix Software for Avio 550/560 Max ICP-OES”, Technical Note, PerkinElmer, 2020

Consumables Used