Polyethylene (PE) is a thermoplastic polymer with variable crystalline structure and a wide range of applications depending on its specific type.

Differential scanning calorimetry (DSC) provides information about key thermal characteristics of polymers including insights into glass transitions, melting point, recrystallization and curing among others. When characterizing polymers, the PerkinElmer Pyris™ DSC 9 provides a simple yet robust solution to differentiate between different grades of the same polymer based on known thermal characteristics. This work will demonstrate how DSC can be used to easily determine the grade of a sample of recycled polyethylene, as well as detect the present of a low concentration of polypropylene in a recycled polyethylene sample. thiết bị DSC Pyris™ 9 của PerkinElmer là một giải pháp đơn giản nhưng mạnh mẽ để phân biệt các cấp độ khác nhau của cùng một loại polyme dựa trên các đặc tính nhiệt đã biết. Nghiên cứu này sẽ chứng minh cách DSC có thể được sử dụng để phân tích polyethylene tái chế xác định cấp độ của mẫu polyethylene tái chế, cũng như phát hiện sự hiện diện của một lượng nhỏ polypropylene trong mẫu polyethylene tái chế.

Experimental

5 mg (+/- 0.5 mg) samples of polyethylene were cut to give a flat shape, providing ideal thermal contact for DSC analysis. Samples were crimped into standard aluminum pans (02190041) prior to analysis using the DSC 9 differential scanning calorimeter (Figure 1). All samples were measured using the following temperature program:

-

- Hold for 1 minute at 50 °C

- Heat from 50 to 180 °C at 20 °C/min

- Hold for 1 minute at 180 °C

- Cool from 180 to 50 °C at 20 °C/min

- Hold for 1 minute at 50 °C

- Heat from 50 to 180 °C at 20 °C/min

This method involves first heating all samples past their melting temperature, then cooling them down at a controlled, consistent cooling rate. This accomplishes two key tasks. The first is ensuring optimum thermal contact between the sample and pan. The second is essentially ‘erasing’ any thermal history the sample might have due to previous processing. This provides far more comparable results than would otherwise be available.

Figure 1. PerkinElmer Pyris™ DSC 9 Differential Scanning Calorimeter.and Established PDEs for Elemental Impurities

Results and Discussion

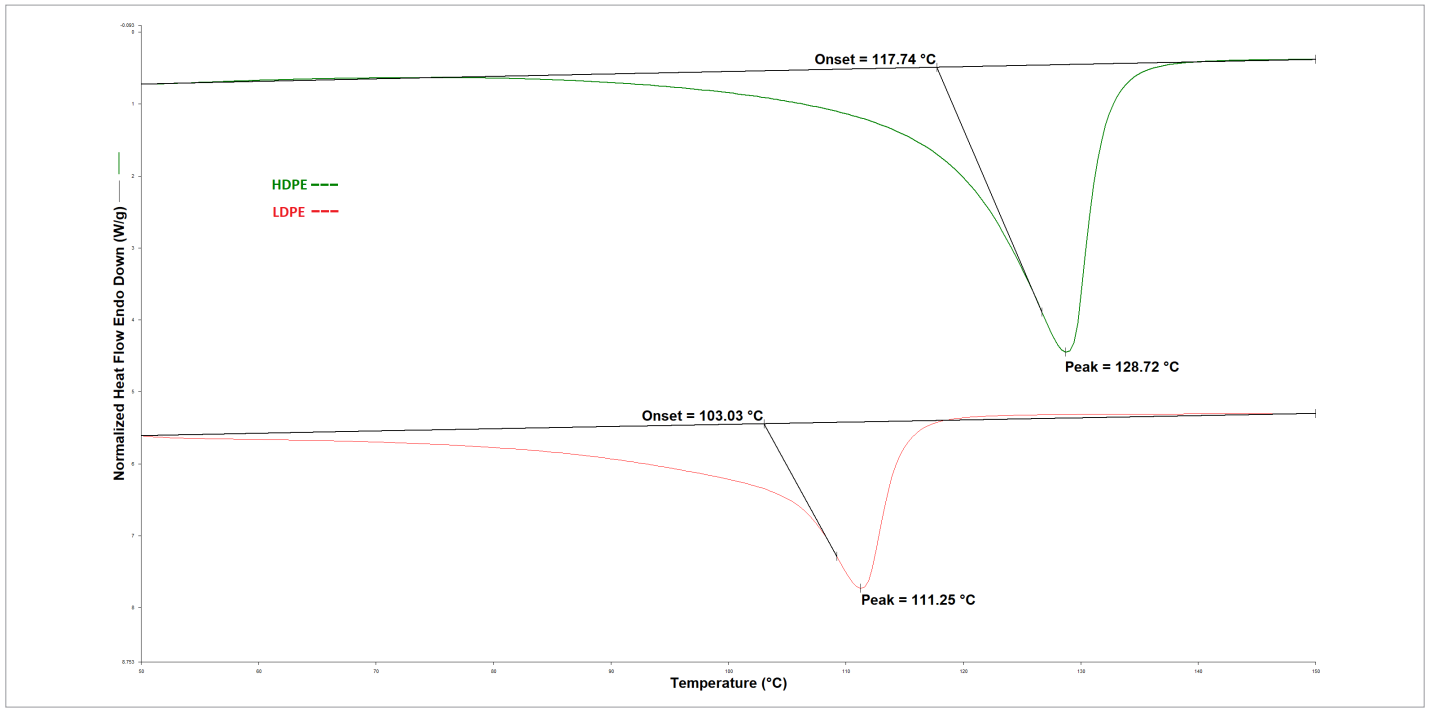

Results from DSC analysis of virgin low-density polyethylene (LDPE) and high-density polyethylene (HDPE) are shown in Figure 2. For both samples, Pyris™ software was used to calculate the melting onset temperature as well as the peak melting temperature.

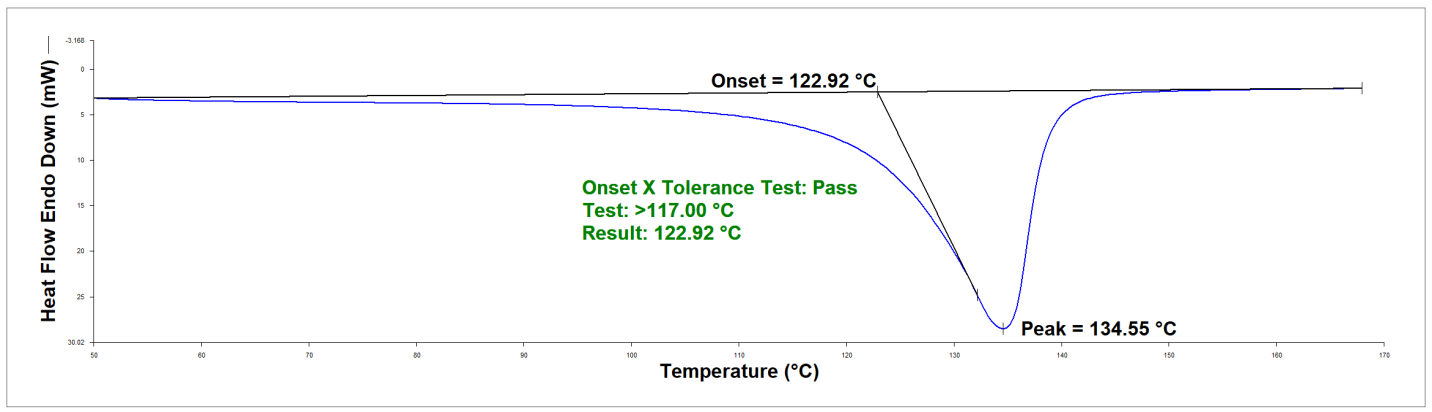

This data may be used as a reference in order to determine the grade of an unknown polyethylene sample. Figure 3 shows the data obtained by a sample of polyethylene with an unknown grade.

Figure 2. DSC results from virgin polyethylene samples.

Figure 3. DSC data obtained from a recycled polyethylene sample.

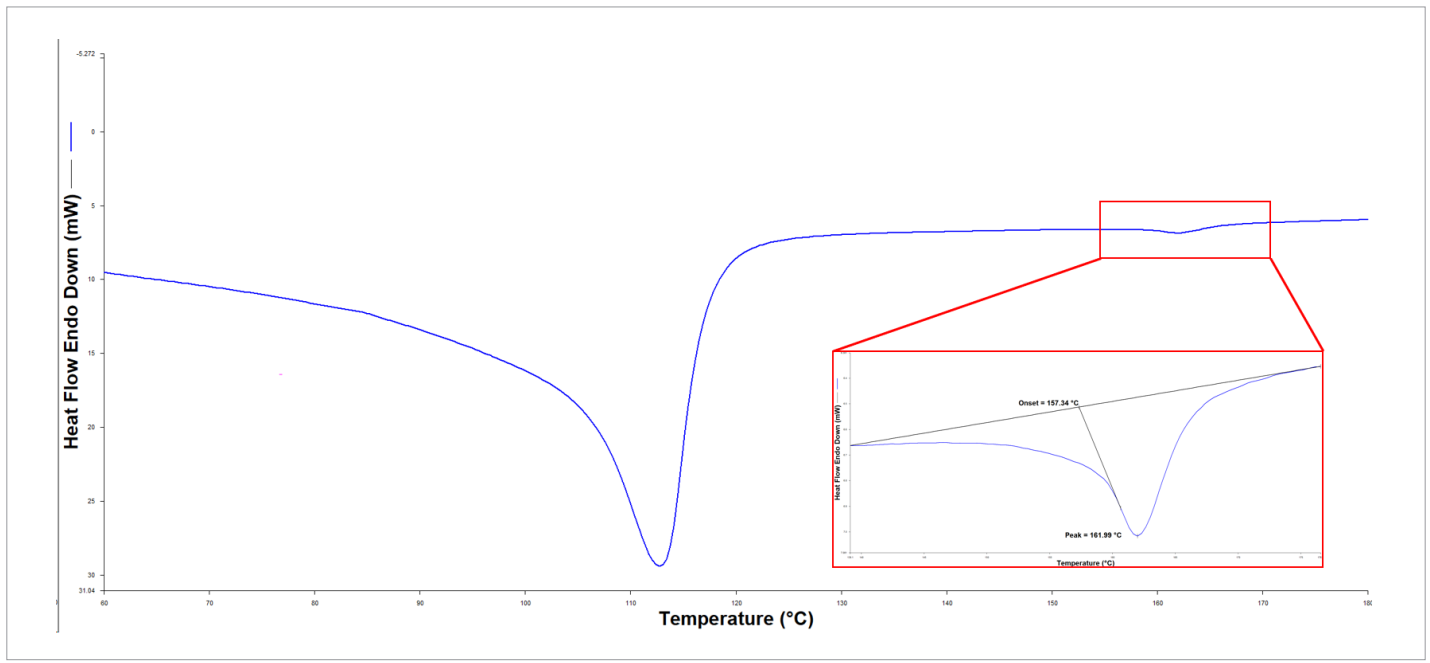

Pyris software allows users to set tolerance test limits. In this case, the limit can be set such that anything with a melt onset temperature above 117 °C (as found from analysis of the virgin polymer) may be deemed to be HDPE. This provides a simple and streamlined method for quickly determining the grade of polyethylene. Another test that may be employed with recycled polyethylene is the detection of polypropylene. Figure 4 shows the DSC collected from a sample that is suspected to contain a small quantity (approximately 2%) of polypropylene.

From this data we can determine the grade of polyethylene by looking at the melting onset temperature (LDPE due to an onset of 101 °C) as well as clearly identifying the peak with a melting point of 162 °C.

Summary

Máy DSC Pyris 9 for PerkinElmer The PerkinElmer Pyris DSC 9 provides a robust yet highperformance solution for polymer analysis. Pyris software may be used to automate data analysis to give a simple yes or no answer regarding the identity of a sample. Furthermore, the high sensitivity of DSC allows for the detection of contaminant polymers even at low concentrations.

Figure 4. DSC data from a sample of recycled polyethylene suspected to contain a small quantity of polypropylene.

Detail app note: perkinelmer/app-analysis-recycled-polyethylene-dsc-9.pdf?u=3ezgsz