The ASTM method D8110-17 titled “Standard Test Method for Elemental Analysis of Distillate Products by Inductively Coupled Plasma Mass Spectrometry (ICP-MS)” 1 describes a procedure for the determination of a few trace elements in light and middle distillate petroleum products using ICP-MS. Traditionally, such analysis was performed by inductively coupled plasma optical emission spectroscopy (ICP-OES) and atomic absorption spectroscopy (AAS), but specifications for some elements have changed and technology with better detection limits, such as ICP-MS, is now required. Contaminants in feedstock can harm refinery processes. Those in petroleum products can compromise the quality of fuels, causing premature breakdown of mechanical equipment, poison catalysts, and impact performance of the final products, such as various chemicals, plastics, and synthetic materials. They also may have harmful effects on the environment when discharged. Light petroleum distillate products, such as naphtha and jet fuel, with low boiling points are usually diluted in a less volatile solvent for analysis, while middle products, such as kerosene, can be analyzed directly.

There are certain challenges in analyzing petroleum products. Volatile samples can destabilize or even extinguish the plasma. Also, carbon may build up in the sample introduction system and deposit on the interface cones. In addition, carbon-based spectral interferences on several analytes of interest can lead to false analytical results. Analysis of Petroleum Products According to ASTM Method D8110-17 Using the NexION 2200 ICP-MS APPLICATION NOTE ICP - Mass Spectrometry AUTHOR Ewa Pruszkowski, Ph.D. PerkinElmer Shelton, CT, USAAnalysis of Petroleum Products According to ASTM Method D8110-17 Using the NexION 2200 ICP-MS Fortunately, these challenges can be easily overcome with PerkinElmer’s NexION® ICP-MS portfolio. This work presents the analysis of petroleum products according to ASTM D8110-17 using the NexION 2200 ICP-MS.3 The NexION 2200, featuring a freerunning 34-MHz RF generator, delivers fast impedance matching to rapidly adjust to changing sample matrices, while the wide-aperture cones of the Triple Cone Interface (TCI) with OmniRing™ technology 4 offer unparalleled resistance to clogging, and most importantly, enhanced sensitivity. Furthermore, the ability to use pure reaction gases, such as NH3 , in the quadrupole-based Universal Cell (UCT)5 is instrumental for removing spectral interferences.

Experimental

Sample and Standard Preparation

For this study, three commercial petroleum products were analyzed representing light naphthas – Odorless Paint Thinner “Mona Lisa”, 100% Pure Odorless Mineral Spirit “Gamsol” and Industrial Paint Thinner “Varsol”. Before analysis, these samples were diluted w/w 1:10 with V-Solv™ ICP Solvent (PerkinElmer, Shelton, Connecticut, USA).

As a method accuracy check, a diluted NIST Standard Reference Material 1634c, Trace Elements in Fuel Oil, was used.

The calibration standards were prepared from the V-26 Wear Metal Standard (PerkinElmer) by dilution in V-Solv. The diluted Wear Metal Standards V-21+K (PerkinElmer) was used as a calibration verification solution. A diluted Co Single Element in Hydrocarbon Oil Standard (PerkinElmer) was spiked into the V-Solv blank, standards and samples, as an internal standard.

Instrumentation and Parameters

In this application note the PerkinElmer NexION 2200 ICP-MS , a single-analyzer-quadruple system with three-quad design described in detail in the NexION 2200 interactive brochure, was employed.

Samples were delivered to the system via a self-aspiration PFA probe to avoid potential problems with peristaltic pump stretching or even deterioration during long hours of operation. The MEINHARD® glass nebulizer aspirated samples at a rate of 200 µL/min. The nebulizer flow was optimized for the best sensitivity and lowered slightly to accommodate the O2 addition (via a spray chamber port) that prevents carbon from building up on the cones. Oxygen flow was 6% of the total nebulizer gas flow. The cyclonic spray chamber was chilled to -5 oC to lower the solvent vapor entering the plasma.

The proprietary quadrupole-based Universal Cell (UCT), pressurized with 100% pure ammonia, through predicable and repeatable reactions provides superior spectral interference removal, improving method detection limits (MDLs) and reliability of results. Instrumental parameters are listed in Table 1.2 hoặc O2 là cách hiệu quả nhất để loại bỏ các nhiễu quang phổ bằng cách chuyển đổi chúng thành nguyên tử hoặc ion có khối lượng khác hoặc tạo thành ion cụm với chất phân tích (Mass Shift) ở khối lượng cao hơn. Các thông số thiết bị được liệt kê trong Bảng 1.

Table 1. NexION 2200 ICP-MS Instrumental Parameters.

Results and Discussion

Calibration Curves

Three calibration standards (10, 20 and 40 ng/g) were prepared from the S-26 Wear Metal Standard by dilution in V-Solv. The V-Solv blank and the standards were spiked with Co as an internal standard to the final concentration of 10 ng/g.

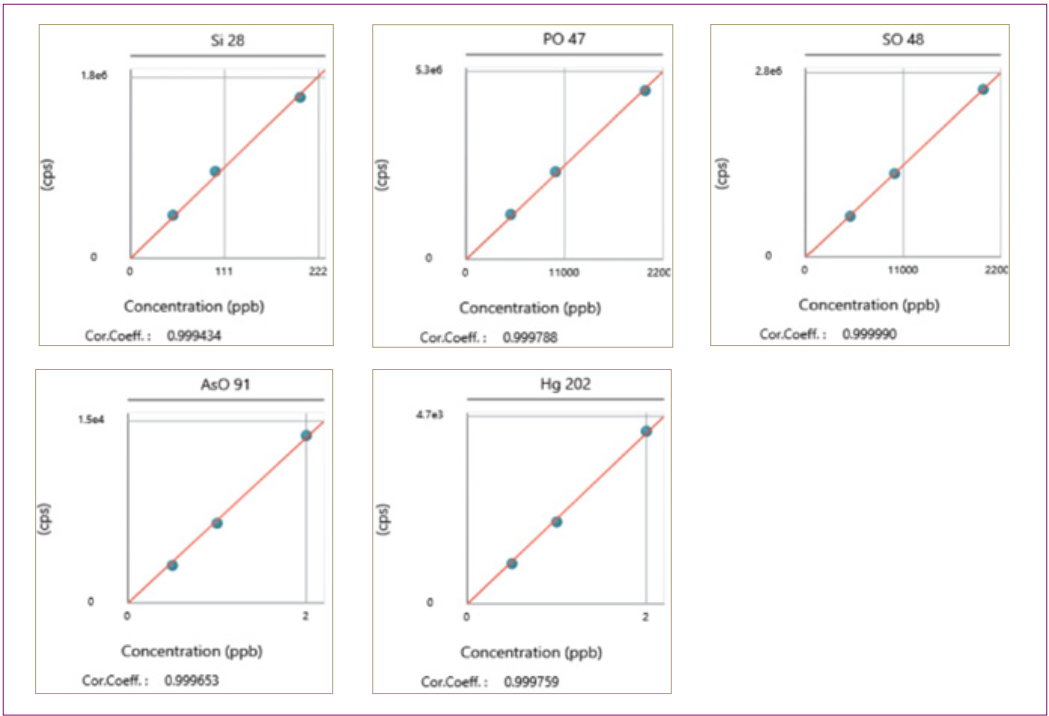

The calibration curves for the elements listed in the ASTM method are shown in Figure 1, all having correlation coefficients > 0.9999.

Figure 1. Calibration curves for seven analytes listed in ASTM D8110-17 method.

Method Detection Limits

According to ASTM D8110-17, method detection limits have to be determined annually or whenever a significant change in background or instrument response is expected, using the following formula: MDL = (t) x (s) where: t = students’ t value for a 99% confidence level and with n–1 degrees of freedom (t = 3.14 for seven replicates) s = standard deviation of the replicate analyses

Table 2. Potential Spectral Interferences from Carbon Species.

Results and Discussion

The ASTM method D8110-17 has specific requirements regarding calibration, check standards, internal standards, QC samples, MDLs, precision, repeatability and reproducibility. We have addressed these requirements through several tests. The method listed Al, Ca, Cu, Fe, Pb, Mg and K as elements to be analyzed for trace contaminants in distillate products, however, a few other elements that can be potential contaminants were added to our tests.

Table 3. MDL Results for ASTM Method Elements (in bold) and 12 others.

QC Results

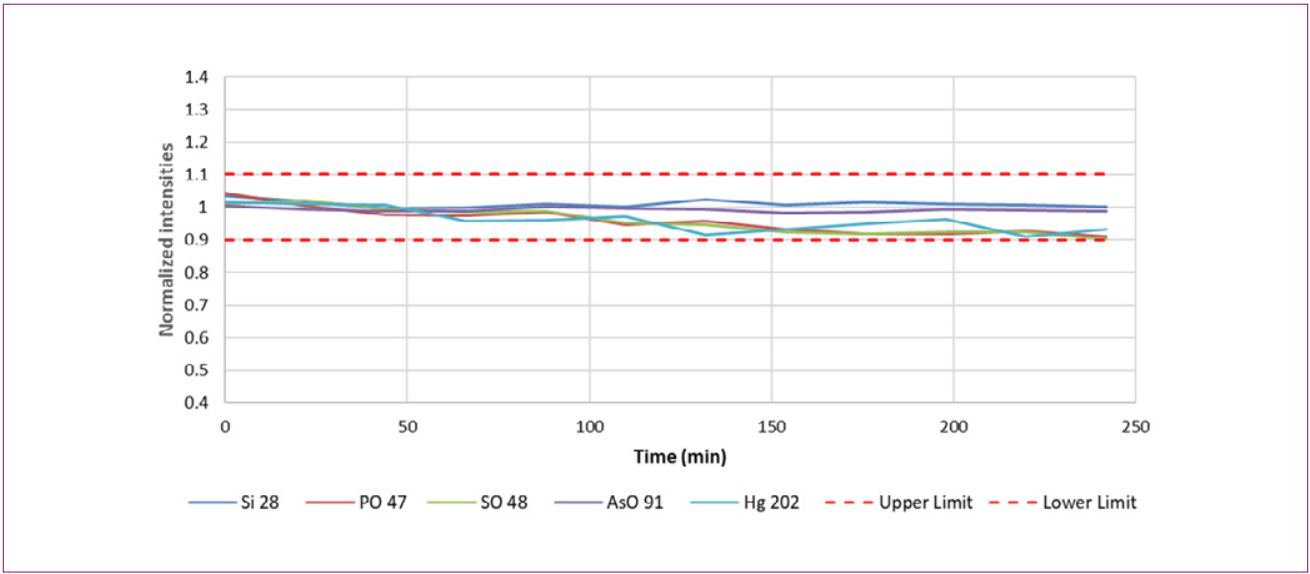

After the calibration was performed, a second source standard, diluted V-21+K, was analyzed as a QC to verify if the results were in agreement with the ± 10% control limit. The correlation was very good, within ± 4% for all tested elements.

Figure 2. QC analyzed every 5 samples during 4-hour run.

Conclusion

Các kết quả được trình bày trong công trình này một lần nữa cho thấy khả năng của thiết bị the PerkinElmer NexION 2200 ICP-MS của PerkinElmer trong việc phân tích hiệu quả các sản phẩm chưng cất dầu mỏ và dầu cho các nguyên tố đã chọn. Sự kết hợp giữa các tính năng độc đáo và thiết kế của NexION 2200 mang lại hiệu suất vượt trội cho một số nguyên tố thách thức mà ngành công nghiệp dầu mỏ có thể quan tâm.

References

- Pruszkowski E., “Analysis of Petroleum Products According to ASTM Method D8110-17 Using the NexION 2200 ICP-MS”, PerkinElmer Application Note, 2023.

- ASTM Method D8110-17, “Standard Test Method for Elemental Analysis of Distillate Products by Inductively Coupled Plasma Mass Spectrometry (ICP-MS)”, ASTM International, 2017.

- “NexION 2200 ICP-MS”, PerkinElmer Interactive Brochure, 2023

Consumables Used

Learn more: perkinelmer/app-nexion-2200-icp-ms-petroleum-products-astm-D8110-17.pdf?u=3ezgsz